POLYCOR™ - properties

POLYCOR™ is a modern, active polymeric anticorrosion pigment designed as an anticorrosion additive for various types of paints.

The application of the latest scientific knowledge and unique know-how has resulted in a product that is both effective and completely safe for the environment. Our polymer corrosion inhibitor is characterised by the following features:

- Significantly better anti-corrosion properties compared to existing solutions

- It is an environmentally friendly technology

- It is easy to use by adding without pre-mixing to the production process

- It is characterised by a wide range of applications in waterborne, solvent-based and powder paint systems

Significantly better anticorrosion properties compared to existing solutions

Laboratory tests have highlighted the superior corrosion protection properties of POLYCOR™ compared to zinc phosphate and calcium phosphate in epoxy and acrylic WB formulations, as well as for epoxy powder formulations. Below are the laboratory test results for these three areas.

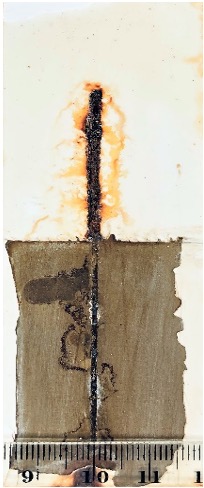

Test results for WB epoxy formulation

The images below show samples with corrosion after application of a double corrosion protection coating after 504 hours of salt spray testing for the corrosion protection product based on BASF’s Watepoxy 1422 and 801 dispersion.

Średnia dla próby DFT/μm: 120

Średnia dla próby DFT/μm: 127

Średnia dla próby DFT/μm: 132

Średnia dla próby DFT/μm: 120

Tests were performed in accordance with EN ISO 9227 on steel plates cleaned to grade St3. Corrosion assessment according to PN-EN ISO 4628.

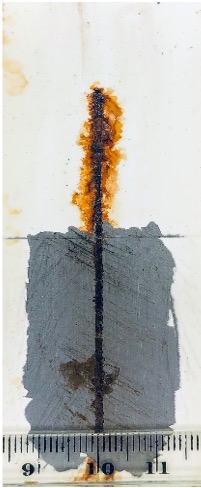

Test results for WB acrylic formulation

The following photos show samples with corrosion after application of the double corrosion protection coating after 504 hours of salt spray testing with Alberdingk Boley’s AC2403 dispersion-based corrosion protection (53% by weight)

Średnia dla próby DFT/μm: 98

Średnia dla próby DFT/μm: 90

Średnia dla próby DFT/μm: 115

Średnia dla próby DFT/μm: 108

Tests were performed in accordance with EN ISO 9227 on steel plates cleaned to grade St3. Corrosion assessment according to PN-EN ISO 4628.

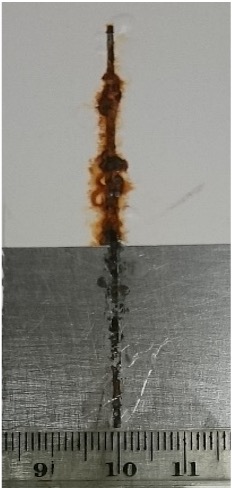

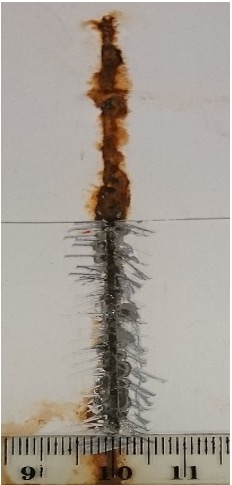

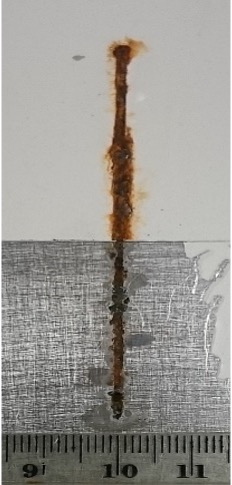

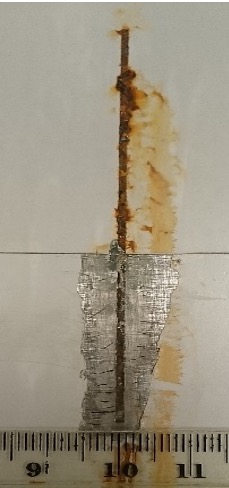

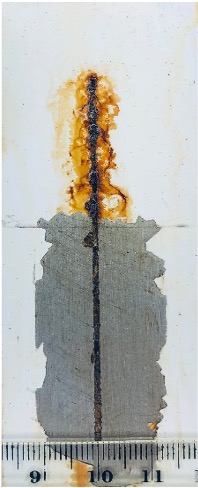

Test results for epoxy powder formulation

The figure below shows samples with corrosion under the coating after 504 hours of salt spray testing for the anti-corrosion formulation based on EPONAC 825 dispersion by SIR Industriale SpA.

Średnia dla próby DFT/μm: 96

Średnia dla próby DFT/μm: 101

Średnia dla próby DFT/μm: 92

Tests were conducted in accordance with PN-EN ISO 9227 on oxilaned plates. Corrosion assessment according to PN-EN ISO 4628.

Eco-friendly technology

Thanks to a uniquely designed and patented synthesis process, POLYCOR™ products are considered to be completely harmless to the environment.

Existing corrosion inhibitors – inorganic zinc phosphate-based, organic liquid and organic solid – are in many cases classified as hazardous to health and the environment. Most of them are toxic to living organisms, irritate the skin and mucous membranes or contribute to cancer.

Our products based on the corrosion inhibitor POLYCOR™ are not classified as hazardous to health and nature. Therefore, they have not been given the safety marks characteristic of other corrosion inhibitors.

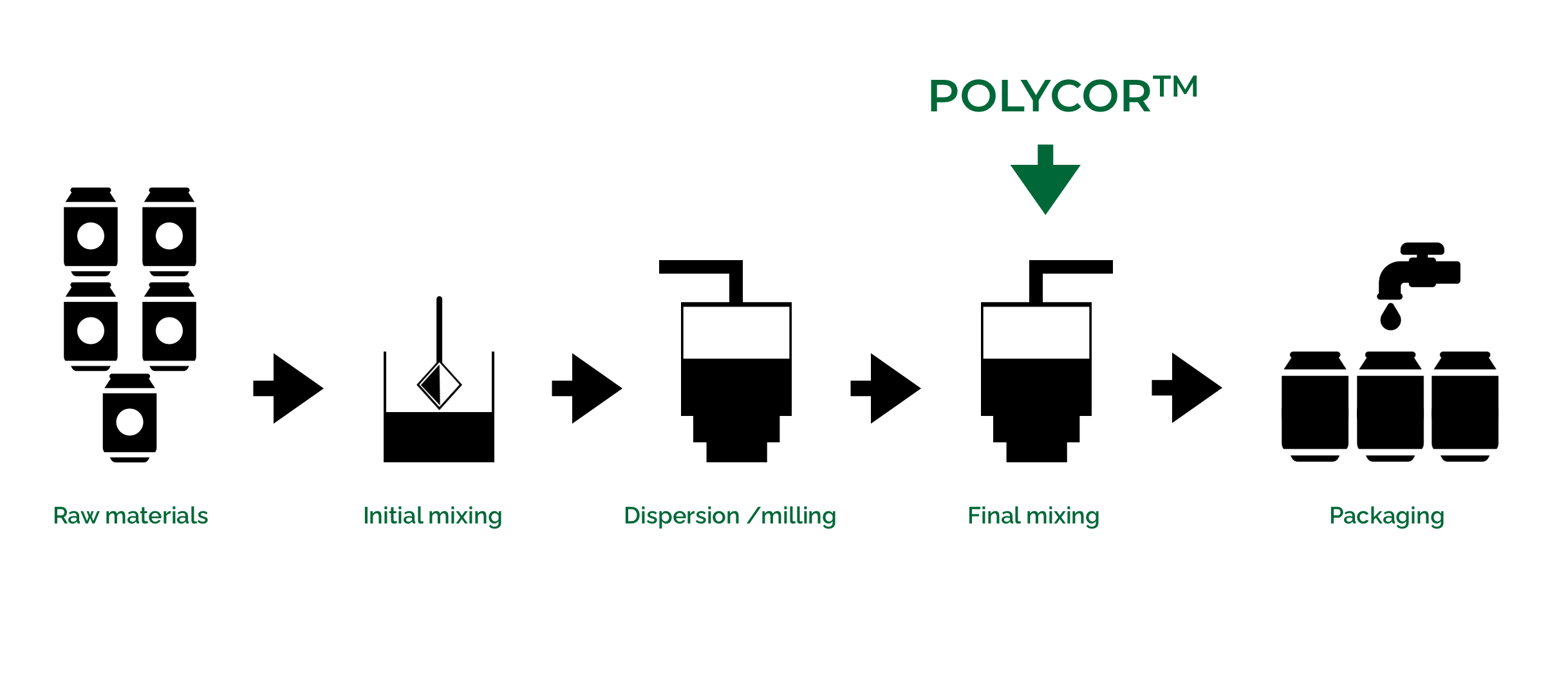

Easy to use by adding without pre-mixing to the production process

Unlike some existing organic inhibitors, POLYCOR™ in the form of a stable aqueous concentrate or solvent paste can be easily added at the final stage of product completion.

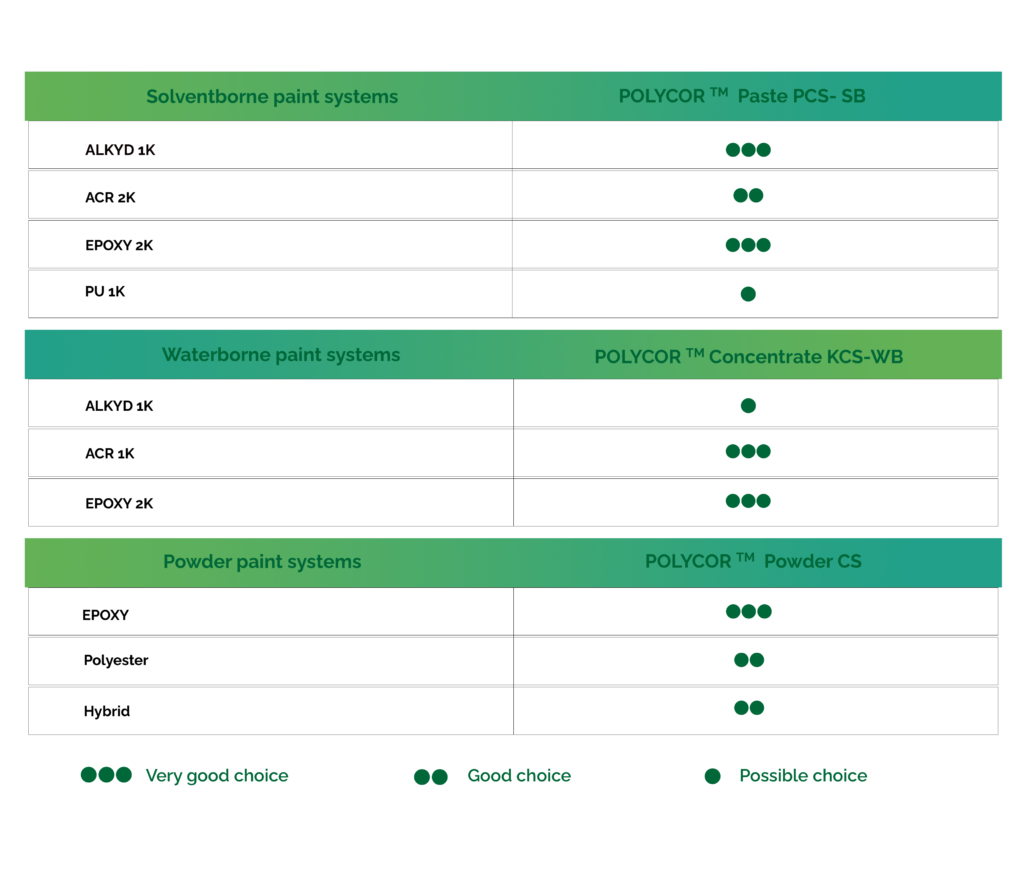

Wide range of applications in waterborne, solventborne and powder paint systems

ADDRESS

R&D Manufacturing

Bierutowska 57-59

51-317 Wrocław

+48 71 302 73 61